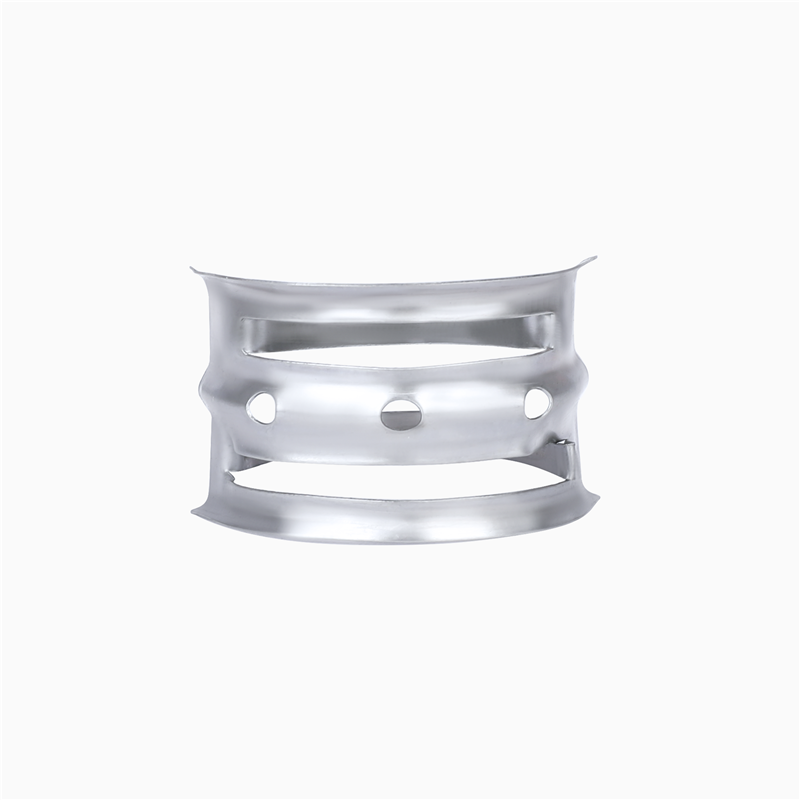

METAL NUTTER RING

Nutter Ring is a king of high performance packing with good geometry structure provides minimum accumulation and maximum randomness. Compared with the corresponding size of pall rings, it can increase the flux by 10%, while the pressure drop was only 40% of pall ring.

Materials and Options

Available in a wide range of materials such as stainless steel 304, 304L, 316, 316L, carbon steel , aluminum and other alloy etc.

Advantage

- Efficiency enhanced by lateral liquid spreading and surface renewal.

- Superior surface utilization in mass and heat transfer, allowing shorter packed bed heights.

- A high performance random packing verified by tests conducted at Fractionation Research Institute (FRI).

- Mechanical form provides maximum randomness with minimal nesting.

Applications and Industries

Desiccation tower, Absorption Tower, Cooling Tower, Washing Tower...etc.

Specifications

|

Size |

Pieces(m³) |

Weight(kg/m³) |

Surface Area(m²/m³) |

Void space(%) |

|

0.7# |

167400 |

176 |

266 |

97.7 |

|

1.0# |

67100 |

178 |

168 |

97.7 |

|

1.5# |

26800 |

181 |

124 |

97.8 |

|

2.0# |

13600 |

173 |

96 |

97.8 |

|

2.5# |

8800 |

83 |

83 |

97.9 |

|

3.0# |

4200 |

66 |

66 |

98.1 |

English

English Español

Español