Packed towers are used as contacting equipment for gas-liquid and liquid-liquid systems.

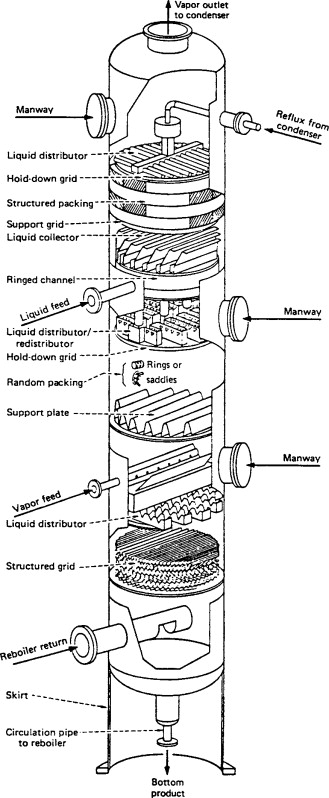

The basic unit consists of:

- shell,

- packing (one or more sections),

- packing supports,

- liquid distributors,

- intermediate supports and redistributors,

- gas and liquid entrance and exit nozzles.

Liquid distribution probably plays the most important part in the efficient operation of a packed tower. A good packing from the process viewpoint can be reduced in effectiveness by poor liquid distribution across the top of its upper surface or the packing sections below any feed inlets or reflux inlets. Many of the mechanical aspects of tower construction and assembly have an influence upon the design and interpretation of tower performance. Every effort should be made to increase the effectiveness of contact between the process streams and to reduce losses by entrainment or wall effects at a minimum expenditure of pressure drop. At the same time, the design must be consistent with the economics dictated by the process and type of construction.

Applications

Applications for tower packing include:

Aeration

Acid gas scrubbing

Catalytic gas scrubbing

Distillation

Precipitation

Particulate removal

Mist elimination

Packed towers are used increasingly in small fractionating towers and absorbers where access is restricted. Their use is also advantageous where corrosion control is essential. Because of liquid-distribution concerns, packing still is usually not recommended for large-diameter columns, or where a high turndown ratio is required. All packings tend to spread liquid as it flows downwards. This characteristic is adequate for dispersing the liquid between distribution points, but not to correct poor distribution across a tower without considerable loss of efficiency.

English

English Español

Español