In the area of Metal Random Packing, several noteworthy tendencies and innovations are shaping the landscape, using efficiency, sustainability, and flexibility. Here are a number of the present day developments on this discipline:

Advanced Materials and Alloys:

Trend: Manufacturers are increasingly more utilising superior materials and alloys, such as stainless steel, high-performance alloys, and corrosion-resistant compounds.

Innovation Impact: These substances decorate the durability and corrosion resistance of Metal Random Packing, extending the lifespan and decreasing the need for frequent replacements. This, in flip, contributes to price financial savings and operational efficiency.

Intricate Geometries and Designs:

Trend: Innovative packing designs with complicated geometries are gaining prominence.

Innovation Impact: These designs maximize the floor location available for mass transfer, extensively enhancing the performance of separation, absorption, and distillation procedures. Industries gain from extended productiveness and optimized resource usage.

Focus on Sustainability:

Trend: Sustainability is a principal topic, with a focal point on eco-friendly substances and environmentally conscious manufacturing tactics.

Innovation Impact: The incorporation of sustainable practices aligns with international environmental goals. Long-lasting materials and decreased renovation desires make contributions to a decrease environmental footprint, making Metal Random Packing an eco-friendly desire for various business applications.

Compliance with Regulatory Standards:

Trend: Adherence to stringent regulatory standards is becoming a priority for manufacturers.

Innovation Impact: Metal Random Packing designs are evolving to satisfy and exceed enterprise-specific guidelines. This guarantees that the packings may be seamlessly incorporated into various industrial procedures with out compromising safety or regulatory compliance.

Expanded Applications Across Industries:

Trend: Metal Random Packings are finding increased programs across diverse industries, together with petrochemical, chemical processing, oil and gasoline, and environmental safety.

Innovation Impact: The versatility of Metal Random Packing makes it a pass-to answer for various procedures, from refining packages to wastewater remedy. The packings' adaptability contributes to their big adoption and effectiveness in addressing industry-specific demanding situations.

Performance Optimization and Cost-Effectiveness:

Trend: There is a focus on accomplishing a stability between performance optimization and price-effectiveness.

Innovation Impact: The latest improvements aim to deliver packings that provide enhanced performance at the same time as final economically feasible. The intention is to offer answers that decrease operational charges over the long time, offsetting preliminary investments with prolonged lifespan and decreased protection requirements.

Technological Integration for Monitoring and Maintenance:

Trend: The integration of clever technology for actual-time monitoring and predictive protection is gaining traction.

Innovation Impact: Smart Metal Random Packing solutions allow industries to reveal performance parameters, identify capacity issues proactively, and optimize maintenance schedules. This guarantees that the packing operates at height performance at some stage in its lifecycle.

In precis, the trendy traits and improvements in Metal Random Packing underscore a dedication to sturdiness, performance, sustainability, and regulatory compliance. These advancements role Metal Random Packing as a essential element in diverse business processes, providing answers that meet the evolving needs of numerous industries even as contributing to a more sustainable destiny.

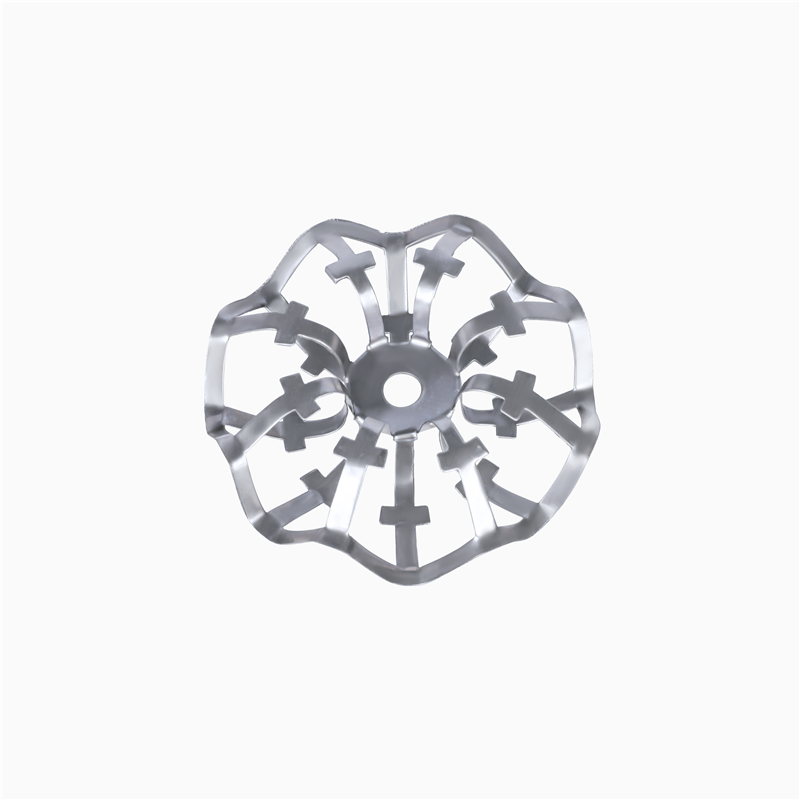

METAL TELLER ROSETTE RING

English

English Español

Español