The Metal Gauze Corrugated Packing is a common shipping and storage medium for many types of goods. It can be produced in a variety of shapes, sizes, colors and designs to suit almost any product or service. Its durability and strength make it a highly effective packaging material. It is also recyclable and environmentally friendly. The boxes can be printed with a variety of graphics including company logos and important contact information. They can be stacked and stored in large quantities to minimize space requirements. The boxes are manufactured at plants that are known as "integrated corrugated plants" or may be shipped to another manufacturing facility for box fabrication. The latter plants are often called "sheet plants" or "converters".

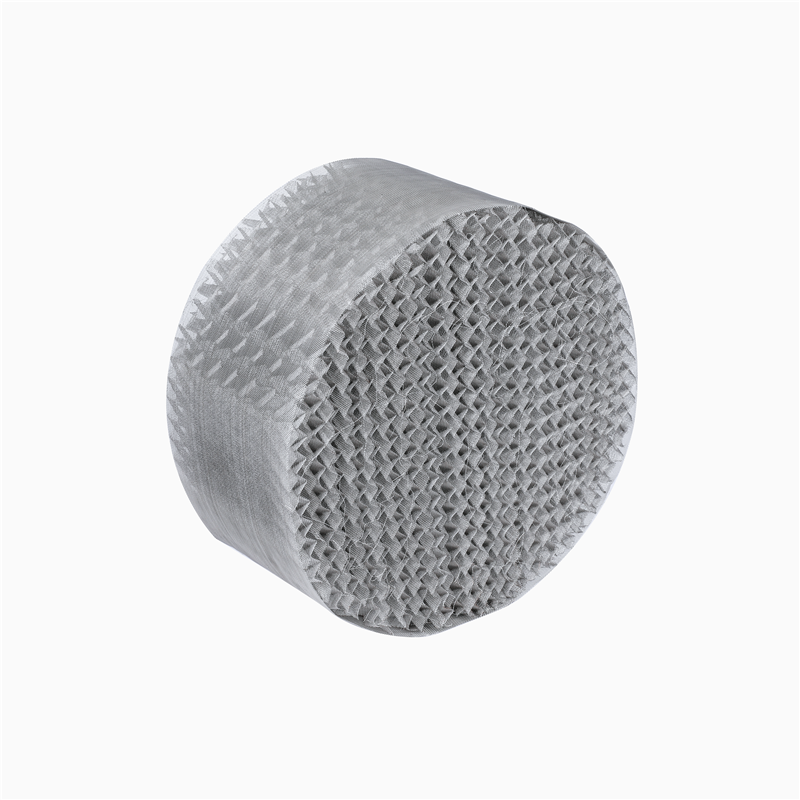

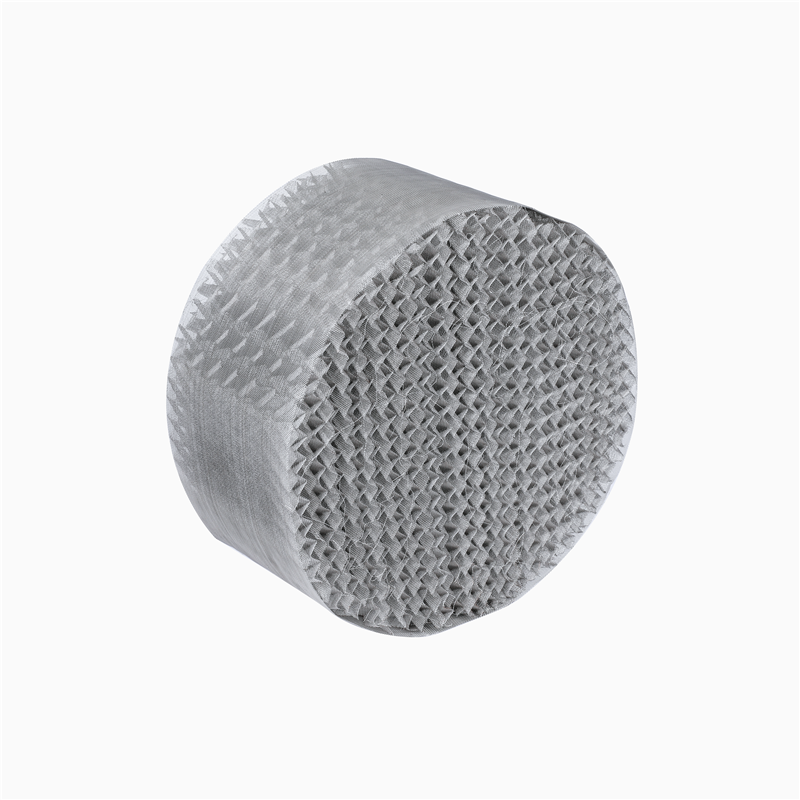

Metal Gauze Corrugated Packing is a structured packing with good performance between the metal gauze structured packing and the random packing. It has a reasonable structure and low cost compared with wire mesh structured packing. It has the following geometric characteristics: large specific surface area, high void ratio, light weight, good radial diffusion, low liquid hold-up and adequate gas contact, etc. It is suitable for vacuum distillation, normal pressure distillation, absorption process of hard to separate and thermally sensitive matters in chemical, petrochemical, fertilizer and metallurgical industry, etc.

The main characteristic of this structured packing is its metal orifice plate punched with holes of f5mm, which can coarsely distribute the liquid on the plates and strengthen the horizontal mixing. The orifice plates have a special puncture microporous structure on the surface, which can increase the surface wetting ability of the packing. This makes the structured packing have an excellent separation efficiency and low resistance with a small pressure drop. This metal orifice structured packing is especially suitable for towers with a large diameter and occasions with heavy gas and liquid loads.

In addition, the structure of this structured packing allows for the liquid spray to spread evenly over a large area in the vapor flow, and prevents the liquid from concentrating on any particular layer. This allows for a higher separation efficiency than other structured packings. In addition, this type of packing can be easily cleaned and has a high stability against temperature fluctuations.

The non-local sensitivity analysis (NLA) of the packing is used to determine the optimum layer configuration. This is accomplished by analyzing the ECT, BCT and non-local critical stress of each layer. In addition, the effect of the grading of the corrugated board on these properties is also investigated. The results show that the ECT and BCT values are significantly influenced by the stiffnesses in the machine direction (MD) and cross direction (CD). The NLA is an extremely useful tool to evaluate and optimize the design of multi-ply corrugated sheeting. The values obtained from the NLA are in good agreement with those derived from experimental tests on a number of packages with different dimensions and grammage of the layers. Moreover, the NLA is capable of predicting the maximum bending stiffness for any perturbation in the layer grammage.

METAL GAUZE CORRUGATED PACKING

METAL GAUZE CORRUGATED PACKING

English

English Español

Español