Metal pall rings are widely used in various chemical and petrochemical processes for mass transfer operations due to their unique design, which provides a high surface area. Here, we'll delve into the characteristics of metal pall rings that contribute to their high surface area:

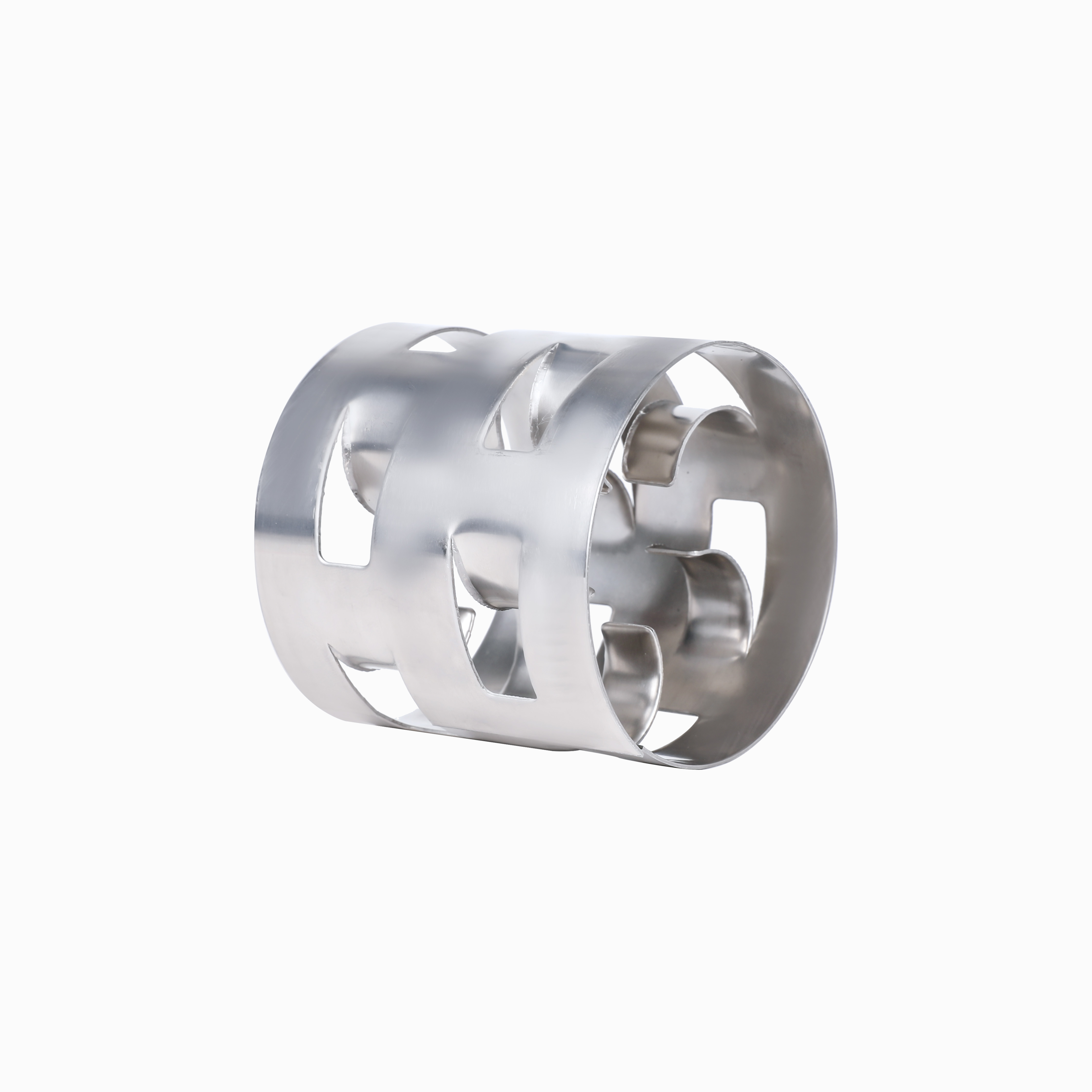

Geometric Design: Metal pall rings have a distinct geometric configuration that sets them apart from other types of packing. They consist of cylindrical rings with internal and external features, such as ribs or struts. These features create a complex, three-dimensional structure with numerous surfaces and crevices.

Increased Surface Area: The internal and external features of metal pall rings significantly increase the available surface area compared to traditional random packing materials. This expanded surface area allows for more extensive gas-liquid contact within the column or tower.

Effective Liquid Film Formation: The presence of multiple surfaces and crevices in the packing helps in the formation of a thin liquid film. This film enhances the efficiency of mass transfer by providing additional contact points for the gas phase to interact with the liquid phase. As a result, the mass transfer rate is improved.

Enhanced Turbulence: The irregular and open structure of metal pall rings promotes turbulence in the gas and liquid phases as they flow through the packing. Turbulent flow further enhances mass transfer by continuously mixing the phases and ensuring maximum contact.

High Void Fraction: Metal pall rings typically have a relatively high void fraction, meaning a significant portion of the packing's volume is open space. This void fraction allows for a greater amount of liquid and gas to flow through the packing, increasing the opportunities for contact and mass transfer.

Uniform Distribution: The internal design of metal pall rings helps distribute the liquid evenly across the packing bed. Even liquid distribution prevents channeling and ensures that all portions of the packing contribute to the mass transfer process.

Improved Separation Performance: The combination of high surface area and effective mass transfer properties results in improved separation performance in applications such as distillation, absorption, and extraction.

Energy Efficiency: Metal pall rings' ability to provide a high surface area and efficient mass transfer while maintaining a relatively low pressure drop makes them energy-efficient in industrial processes. This is particularly important in applications where minimizing energy consumption is a priority.

In summary, the high surface area of metal pall rings is a fundamental characteristic that makes them well-suited for mass transfer operations in various industrial applications. Their geometric design, which creates an intricate network of surfaces and crevices, facilitates effective gas-liquid contact, leading to improved separation efficiency and reduced energy costs in chemical and petrochemical processes.

English

English Español

Español